Add to Cart

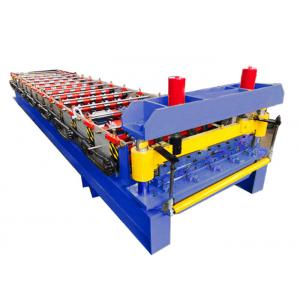

High Speed Automatic IBM Metal Galvanized Steel Roof Sheet Panel Roll Forming Machine

Roof Panel Roll Forming Machine Features

1. The hand wheels on both sides ensure that the raw materials are in a straight line, and the hand cutter can easily change the coil color or save materials

2. Hidden motor and hydraulic pump station can help you save space, and the machine looks more beautiful.

3. 8.8 screws and bolts shall meet the export standard. Rollers shall be processed by CNC lathe and plated with hard chromium. Shafts shall be processed by keyway to ensure simultaneous operation with rollers. The firm side wall connecting rod ensures the stability of roll forming machine.

4. We use square welded tubes for machine frame, and roller material use Cr12 with heat treatment.

Processing flow diagram of roll forming machinery

Decoiler→ Feeding → Roll forming → Measure length → Hydraulic cutting → Output table

Roof Panel Roll Forming Machine Components

| Item | Name | Qty |

| 1 | Manual Decoiler | 1 set |

| 2 | Feeding platform with hand cutting system | 1 set |

| 3 | Main forming system | 1 set |

| 4 | Hydraulic cutting system | 1 set |

| 5 | Hydraulic pump station | 1 set |

| 6 | Electrical motor | 1 set |

| 7 | PLC control system | 1 set |

| 8 | Touch screen operation | 1 set |

| 9 | Finished products receive table | 1 set |

| 10 | Safety shield(optional) | 1 set |

Technical Parameters of Roof Panel Roll Forming Machinery

| No. | IBR Metal Roof Sheet Panel Roll Forming Machine | |

| 1 | Suitable material | PPGI/Aluminium sheet/galvanized sheet/various sheet plates |

| 2 | Thickness of coil sheet | 0.3-0.8mm |

| 3 | Coil width | 925mm |

| 4 | Effective width | 686mm |

| 5 | Material of main frame | 350H steel |

| 6 | Diameter of Soild shaft | 70mm, high grade 45# steel |

| 7 | Roller | High grade 45# steel, quenched and tempered treatment, hard chrome plated 0.05-0.07mm |

| 8 | Thickness of middle plate | 16mm, 45# steel plate |

| 9 | Forming station | 23 rows |

| 10 | Drive type | By chain(1.0 inch), link bearing model 6210 |

| 11 | Power of main motor | 5.5 kw, Lichao, Shanghai, with reducer |

| 12 | Sidewall connection bar | 25mm, zinc plated |

| 13 | Forming speed | About 12-18m/min |

| 14 | Hydraulic pump station | 4.0 kw, 40# hydraulic oil |

| 15 | PLC | DELTA(TAIWAN)/Mitsubishi |

| 16 | Material of razor blades | Cr 12, quenching 58-62℃ |

| 17 | Frequency converter | It has the advantage of slowing down before cutting, to ensure the length accuracy ±1mm, far better than industrial standard ±3mm. |

| 18 | Frequency changer | 1 set |

The Referred Photos of Dual Layer Roof Forming Machinery